Life-cycle planning for your facility assets may not be the central discussion in your business planning meetings, but this client’s bustling Operations Center in Portland, Oregon is a two story, 365,000 square foot epicenter… and life cycle planning is required. With over 11 departments, the facility houses a call center, collections, customer service, printing operations, human resources, payment processing, fraud department, marketing, mail, equipment testing, and an engineering department, plus two data center facilities. This Operations Center employs approximately 1,700 people, and has space to spare for rental of a second data center and offices. Knowing their mechanical equipment and performing preventative generator radiator replacements ensures their facility runs to their 24/7/365 requirements.

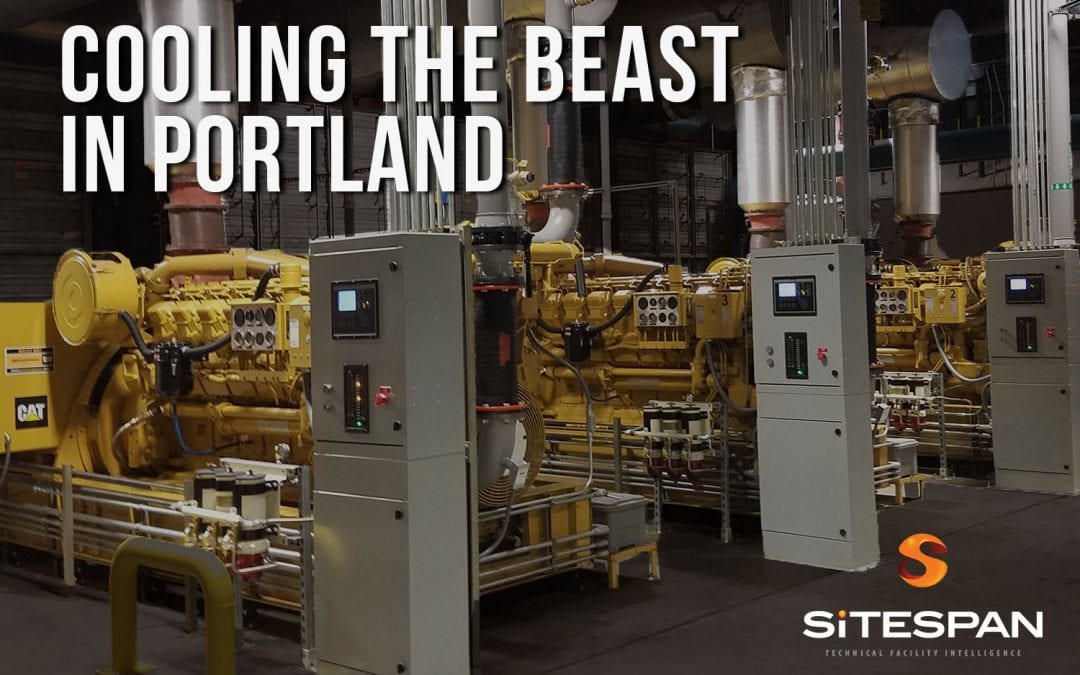

Inside the heart of the facility is one of the corporation’s mission-critical data centers that provides data processing and record keeping activities. These departments work around the clock and require a reliable 24/7 power backup. To ensure maximum reliability, SiTESPAN upgraded fuel storage and delivery systems, as well as making upgrades to the generator controls. To continue in the facility’s life-cycle planning, SiTESPAN next replaced four generator’s remote radiators while maintaining the business requirements of backup and redundancy. It was critical to preserve the facility’s operations by having two generators powering the facility while the third remained available for redundancy. The in-depth process and engineering for this project meant running 650 linear feet of new piping from the Caterpillar Generators housed indoors to the Young Touchstone Radiators on the roof one story above. Radiator replacement is critical to the mechanical system’s life-cycle planning as each unit can remove 62,000 BTU/min (the equivalent of roughly 79 home air conditioners working at the same time), with the fan capable of moving 51,441 ACFM. If there is a failure, or lack of meeting the required heat rejection in this system, the generators will overheat, and the facility will be without power during a utility outage. This further illustrates the importance of life-cycle planning for every aspect of your facility.

Along with replacing the HB 40N Young Touchstone Radiators, SiTESPAN relocated the power and disconnect units for each radiator. This allows the building technician a much shorter walk to turn the power on and off for safety, service, and isolation. Each horizontal radiator and expansion tank had to be pre-assembled prior to being hoisted by crane over a 40-foot wall into the walled mechanical yard. Properly placing the radiators into the mechanical yard required SiTESPAN to modify the beam structure of the elevated structural steel platform to support the 5,270 lbs. units and to modify the surrounding grating.

By completing the replacements, the client’s life span for the generator equipment has been extended another 25 years. To keep the new radiators performing at optimal capacity, the client will maintain monthly equipment testing.

Need a Facilities Health Check?

Ready to eliminate downtime for your mission critical data center? SiTESPAN offers a wide range of services to identify unforeseen problems and will recommend the solutions you need to keep your facility operating at 100%. Feasibility Studies, MEP System Audits and Operation MOP and SOP reviews are all great places to start.

913.568.0448

Connect with us!